Aluminum Extrusion Finishing & Assembly

High-Quality Finishing Services

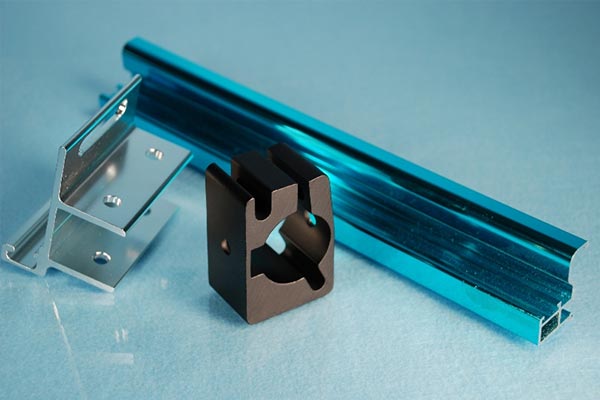

Unique Extrusions provides aluminum extrusion finishing and assembly with the goal of superior quality. We offer a complete line of mechanical finishes, powder coating, and anodizing with an array of finishes to give your aluminum extrusion an appearance your customers will be proud of.

Secondary Finishing

Powder Coating

Powder coating is a type of coating that is applied as a free-flowing dry powder. This is different from the conventional wet paint types of coatings. Whereas wet paint is applied using an evaporating solvent, powder coat is applied by electrically charging the metal and adheres to the metal electrostatically. The powder is then baked on in a curing process usually under heat.

System features/benefits include:

- line maximum length 30’

- RoHS compliant coatings

- Infrared and convection over for faster curing of powder

- 8 automatic and 2 hand spray units

Anodizing

Anodizing is one of the most common and durable chemical finishes in the aluminum industry. It not only improves the final look of the part but also adds a protective layer to the aluminum.

Types

- Standard

- Satin Clear

- Special Colors available

- Two Step

- Black and bronze

- Bright Dip

- Clear

- Special colors available

- Hardcoat

- Clear and Black

- Special Colors available

Assembly

Our facilities include an assembly division where we can completely assemble your finished product and ship directly to your customer!

Contact us today to become your private label manufacturer!

Learn More About Our Aluminum Extrusion Finishing & Assembly Today

For more information or to request a quote, please contact us at 860-632-1314 or click the button below. We look forward to exceeding your expectations!

As one of the largest value-added aluminum extruders in the country, Unique Extrusions, Inc. offers high-quality aluminum products and services nationwide.